Advanced Composite Board Solutions for Footwear and Beyond #

BI-FIT board technology represents a significant advancement in the production of composite plastic boards, including polypropylene (PP) and polyethylene (PE) boards. Developed as a proprietary and patented solution, BI-FIT is recognized in Taiwan, China, the United States, and other countries for its innovative approach to material integration and sustainability.

Redefining Midsole Materials and Manufacturing #

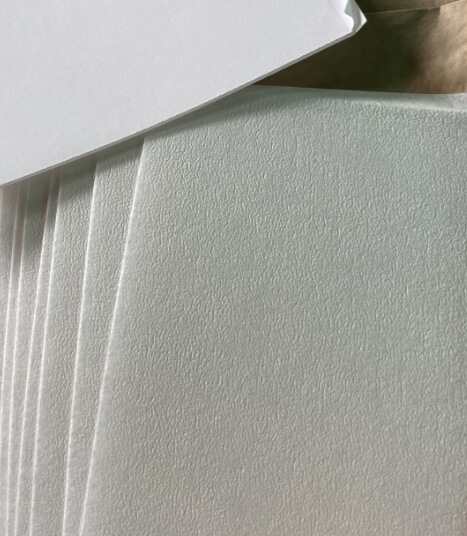

Ying Pao Chia has transformed the traditional midsole manufacturing process by integrating plastic materials with fabrics. This innovation allows BI-FIT to replace conventional paperboard midsoles, offering improved support, cushioning, waterproofing, lightweight properties, and enhanced durability. The technology enables direct integration of fabric and plastic during production, eliminating the need for toxic adhesives. This not only simplifies the adhesion process to other materials but also reduces health and environmental risks.

A standout feature of BI-FIT is its ability to incorporate multiple hardness levels within a single piece. The front end of the board can withstand up to 90° of bending resistance, while the back end maintains rigidity, resulting in improved comfort and fit for end products.

Commitment to Environmental Sustainability #

BI-FIT boards are designed with versatility and ease of processing in mind, making them suitable for a wide range of products and market segments. Ying Pao Chia adheres to the Global Recycling Standard (GRS 4.0), utilizing over 80% recycled PP or PE plastic in the production of BI-FIT boards. This commitment to sustainability supports the ongoing development of environmentally responsible plastic board materials.

Key Features of BI-FIT Board #

- Integrated One-Piece Patented Technology: Unique to composite boards, ensuring seamless integration of materials.

- Superior Cushioning: Enhanced rebound performance compared to traditional materials.

- Waterproof Construction: Fabric is embedded within plastic sheets for reliable waterproofing.

- Support and Stiffness: Delivers excellent support and rigidity for demanding applications.

- Durability: Flexible one-piece molding ensures long-lasting performance.

- Easy Processing: Suitable for cold pressing and die cutting, streamlining manufacturing.

- Adhesion: Strong gripping and bonding capabilities for easy attachment to accessories.

- Bending Resistance: Capable of withstanding up to 90° of bending.

- Temperature Range: Functional between -10°C and 70°C (varies by material).

- Hardness Range: Shore D 45 to 75 degrees, with options for single or double hardness and material combinations.

- Size and Thickness: Maximum width of 45cm, length up to 110cm, and single sheet thickness up to 8mm.

Product Offerings #

- Composite Plastic Boards: Seamlessly integrate plastic with fabrics or other materials, tailored for diverse applications and market needs.

- Polypropylene (PP) Boards: Non-toxic, lightweight, and heat-resistant, with customizable hardness.

- Polyethylene (PE) Boards: Noted for cold resistance, chemical resilience, and electrical insulation, with dual hardness options on a single board.

Plastic Composite Board - Ying Pao Chia

Plastic Composite Board - Ying Pao Chia Ying Pao Chia Polypropylene PP Boards Supplier

Ying Pao Chia Polypropylene PP Boards Supplier Polyethylene Board | Ying Pao Chia

Polyethylene Board | Ying Pao Chia